Systems Engineer

Norsk Titanium AS

- Frist Snarest

- Ansettelsesform Fast

Are you an analytical and hands-on Systems Engineer interested in additive manufacturing?

Norsk Titanium is pioneering a new era of on-demand metal additive manufacturing that will revolutionize the raw material supply chain. We are the world’s first and only OEM qualified supplier of additively manufactured structural titanium components. At Norsk Titanium, we are committed to mutual growth and success. Our innovative team provides training and mentorship from global subject matter experts.

We aim to strengthen our engineering team with a Systems Engineer to support our machine design on new and already established systems. In addition, the function will be responsible for NTi’s service and maintenance plans and for the machine platform Calibration system. You will be a part of the Eggemoen Technology Center team working with experts within metallurgy, process control, software development, image processing, mechanical design, automation, and manufacturing. The role will also be key in supporting the calibration team at our US production facility.

What your day looks like:

Develop and maintain specifications, RCMs and related project documentation for new and upgraded machines according to NTi’s Systems Design Process

Lead projects for new or improved machine functions from ideas to rollout on production machines in the US

Take ownership of the company-wide machine service, maintenance and calibration system, including methods, procedures, and routines

Maintain and enhance service plans for current and next-generation machines, including spare parts lists, troubleshooting guides, and preventive maintenance manuals

Continuously improving maintenance plans for current and next-generation RPD® systems

Support service and maintenance tasks across global sites as required

Contribute to continuous improvement programs across the existing machine fleet at various sites

Prepare for RPD® machine leasing and sales

We’re thrilled to find Candidates with:

A bachelor's or master's degree in systems engineering, automation, mechanical engineering, or a related field

A minimum of 3 years’ experience in the service and maintenance of industrial production equipment

Solid knowledge of industrial standards and engineering best practices in equipment calibration

Hands-on experience in industrial process improvement

The ability to work in a cross-functional, industrial, and international environment

An analytical and collaborative approach to technical challenges

A structured and detail-oriented working style

We have a lot to offer you:

A highly skilled and multidisciplinary engineering environment with creative and talented colleagues

International and good work environment

Interesting and challenging work assignments

The chance to make huge improvements and to see immediate results

Independent tasks and projects in combination with teamwork

Company Fun Club

Good pension and insurance plan

Competitive compensation

Cafeteria serving delicious food

Ferdigheter

- Automatisering

- Dokumentasjon

- Forebyggende vedlikehold

- Ingeniørkunst

- Kalibrering av utstyr

- Kontinuerlig forbedringsarbeid

- Skrive spesifikasjoner

- Vedlikehold av industrimaskiner

JobbMatch

BetaEr du kvalifisert for jobben?

Nysgjerrig på om du kvalifiserer til denne jobben? Med JobbMatch får du umiddelbar tilbakemelding på hvor godt din profil matcher stillingsutlysningen.

Om arbeidsgiveren

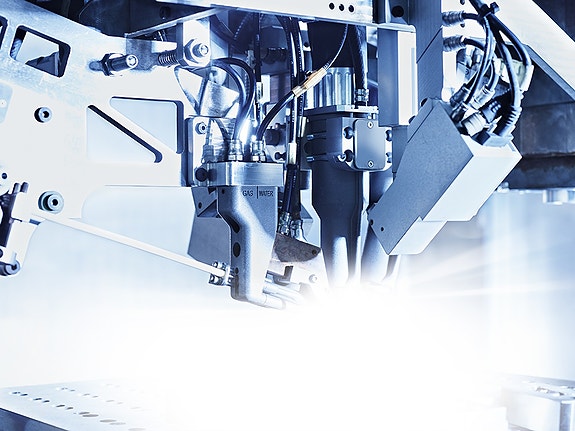

Rapid plasma deposition

Norsk Titanium rapid plasma deposition (RPD®) is a commercial aerospace OEM-qualified additive manufacturing process that delivers structural titanium parts with reduced lead time and cost. RPD® technology revolutionizes industry by pioneering a new era of on-demand metal additive manufacturing. The payoffs are astounding: less titanium, less machining, less lead time, and less inventory. These benefits give our customers increased flexibility and major cost savings.

Om arbeidsgiveren

Norsk Titanium RPD® process is a commercial aerospace OEM-qualified additive manufacturing process that delivers structural titanium parts with reduced lead time and cost. RPD® technology revolutionizes industry by pioneering a new era of on-demand metal additive manufacturing. The payoffs are astounding: less titanium, less machining, less lead time, and less inventory. These benefits give our customers increased flexibility and major cost savings. Norsk Titanium’s Technology Center is located at Eggemoen, Ringerike and our full-scale production center in Plattsburgh, NY.

- Sektor: Privat

- Sted: Flyplassveien 20, 3514 Hønefoss

- Hjemmekontor: Delvis hjemmekontor

- Bransje: Industri og produksjon, Luftfart, Metaller og mineraler

- Stillingsfunksjon: Automasjon og instrument, Ingeniør, Mekanisk

- Arbeidsspråk: Engelsk

Nøkkelord

systemingeniør, kalibreringssystem, additiv produksjon, Flyindustri, prosjektledelse

International and good working environment (1/8)

Annonseinformasjon

- FINN-kode 422703031

- Sist endret